About Substrates

Substrate vs Board, what’s the difference? Boards and Substrates are common electronic terms and often mingled. Advanced substrate technology is scaling-up to larger panel sizes similar to boards, and boards are scaling-down to feature sizes similar to substrates. When defining the terms, substrate vs board may best be differentiated by their application. Substrates serve as the foundation for integrated circuit packaging. Boards are used to physically support and electrically connect multiple components such as packaged integrated circuits. Boards can be further differentiated into Flexible Circuit Boards (FCB) and Printed Circuit Boards (PCB). ASI is rapidly developing advanced technology to meet the demand for fine feature large format flex substrates with feature sizes down to 1um. The new technology includes Au-on-Polymer (Nobleflex™) and Cu-on-Polymer (Ultraflex™). Nobleflex and Ultraflex can provide solutions for board and substrate applications.

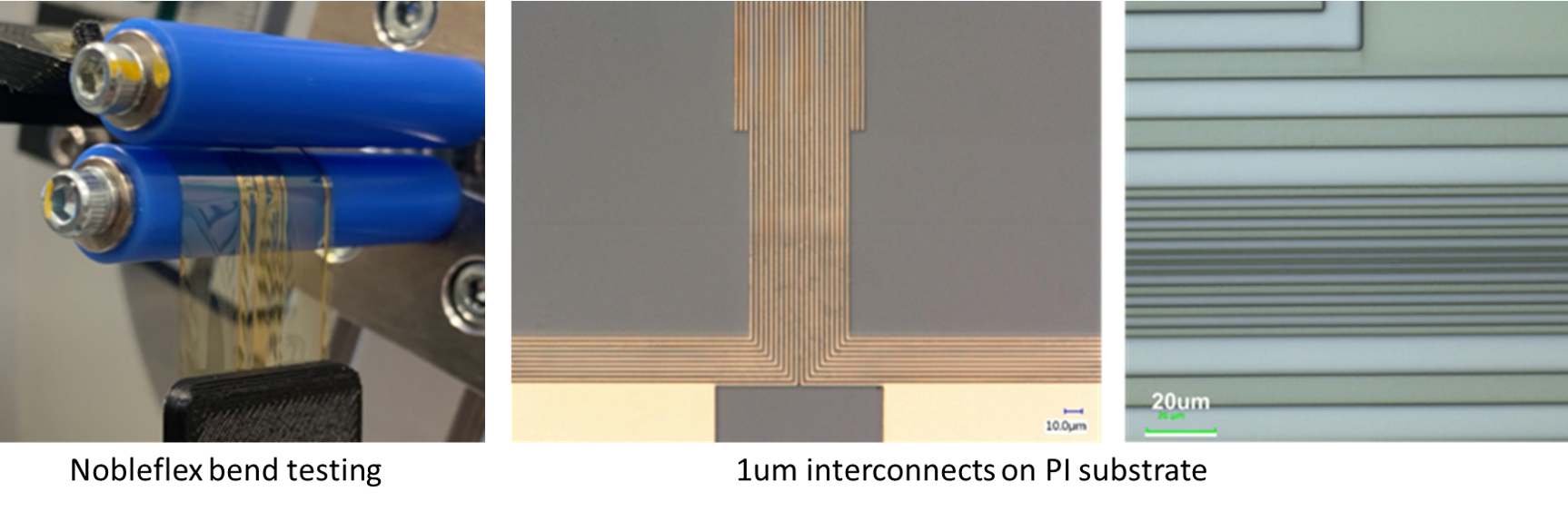

Unlike conventional boards and substrates, neither Nobleflex or Ultraflex utilize adhesive layer lamination of metal and substrate layers. This enables extreme durability for applications subject to mechanical stress such as bending and twisting. Traditional flex generally fails 5mm RoC bending at 1,000 to 2,000 cycles. Nobleflex and Ultraflex exceed 100,000 cycles. Nobleflex/Ultraflex architecture also provides high temperature performance well beyond that of traditional flex. Most significantly, Nobleflex and Ultraflex multi-layer substrates and boards are available with 10um vias and 1um features.

Nobleflex and Ultraflex advanced substrates with 1µm feature capability are now available to support new product development and research projects. For more information on using Ultraflex or Nobleflex for your new product or project contact: sales@americansemi.com. Process data sheet downloads are available below.