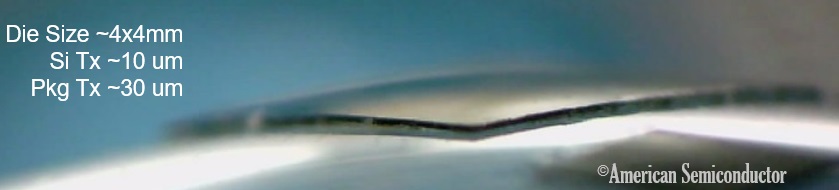

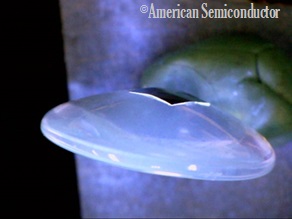

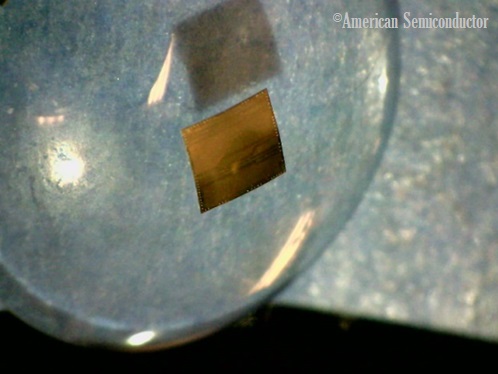

In another display of American innovation, American Semiconductor (ASI) demonstrated spherical IC assembly resulting from continued research and development of the U.S. company’s Semiconductor-on-Polymer WLCSP process. ASI is well known for making the thinnest ICs in the world by applying its Semiconductor-on-Polymer WLCSP process to a variety of chips. Applications to date have focused on utilizing the radically thin advanced packaging technology’s ability to bend or twist. The new work demonstrates dome shaped or “Hemi” ICs that enable advances in smart-contacts, ocular implants and image sensors.

If you are interested in collaborating in regards to this innovative technology, let us know via our Contact Page or our email at sales@americansemi.com